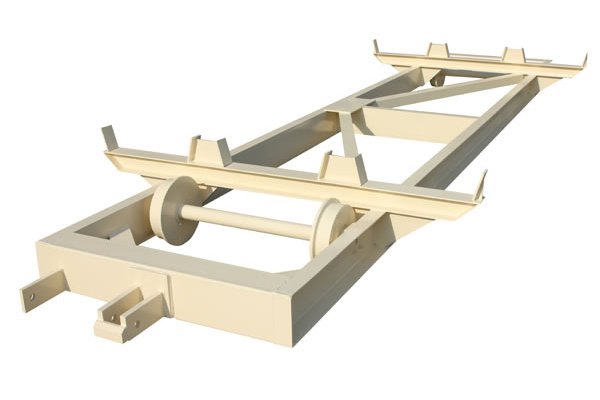

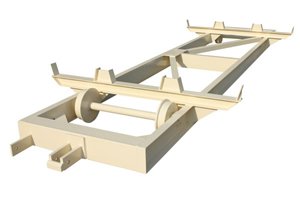

Autoclave Cart

The hardening car, located at the autoclaving section, is used for the material conveying in the AAC production line. It can endure the high temperature and high pressure environment in the autoclave, and won’t get jammed or deformed.

The hardening cars are initially on the rails in grouping area. Then the divided AAC cakes will be transferred onto the cars by special lifting hoist, and grouped and hauled into the autoclave by a traction machine. After the autoclaving process is completed, hardening cars will be pulled out to the finished product area for laying down the AAC blocks/panels. Then the car will return to the initial place for next round. Commonly, driven by traction machine, a car can carry two or three cakes each round.

- The car frame is made from sectional steel which has great toughness and simple structure. A base plate guiding mechanism is mounted for the rapid placing of the plate.

- In the wheel unit of the hardening car, you can find several important components like wheel, axle, bearing, and so on. The wheel surface has been treated by quenching technique, thus excellent durability can be obtained The special structural design of the wheel can ensure wheel's amazing resistance to high temperature and high pressure environment in the autoclave.

Get In Touch

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of TEEYER is the whole line equipment for AAC block and panel production. TEEYER aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, TEEYER Company set up in the year of 1989, with 160.7 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

-

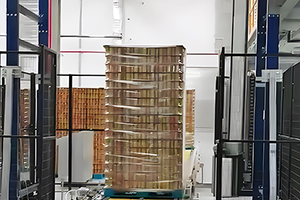

- Rotating HoisterFinished squeezed, blocks will be lifted by rotating hoister, on the length 1.2m direction, after 90 degree rotating, the blocks will be put in cross directions on the pallet.

-

- Finished Product Conveyor LineThe finished product conveyor line is used for block conveying at the packaging section. As a chain conveyor...

-

- Packaging MachinePackaging machine will strap goods in horizontal direction or vertical direction automatically, ready for storage or shipment.

-

- Stretch Film MachineUsing stretch film to cover packages outside, to protect goods from water or dust.To realize separation on 5cm...

-

- Production Control SystemDCS automation control system is composed of Siemens PLC hardware, that is decentralized control...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی