Customized EPC Service

- Providing All-round One-stop Service is Our Aim!

- In 1994, TEEYER started to manufacture complete set of AAC production equipment.

- In 1996, besides equipment manufacturing, TEEYER provided process design, installation service and automation control system.

- In 2008, TEEYER completed the first EPCM AAC project (Sichuan Huaxi project).

- In 2010, TEEYER set up the first fully-localized AAC panel production line (Fuyang Hanjia project).

- Up to 2020, over 1.000 AAC production lines have been completed by TEEYER, among which more than 150 sets of AAC production lines were sold to over 20 countries and regions.

- TEEYER has more than 80 research and development personnel, and maintains long-term school-enterprise cooperation with Jiangsu Institute of Technology, Changzhou Institute of Technology and other universities.

- A number of self-owned process designers work in TEEYER, meanwhile in several projects TEEYER keeps in-depth cooperation with Wuhan Building Materials institute, Beijing Jiandu Design Institute and Northeast Architectural Design Institute, etc.

- TEEYER has a full range of intelligent control system design system, automatic control system design, robot system development (Auto mesh-hanging, Auto packaging and Auto cutting blades replacing), MES system development (production information management system), remote fault diagnosis and support services ability, cloud production & marketing information system storage and Internet information query system services. TEEYER self-owns dozens of electrical control, database and secondary program developers, meanwhile closely cooperates with many professional automated installation service companies, so as to compete with the world-class European equipment on the same stage, aiming to achieve the goal of "Made in China 2025"

- More than 40 project engineers of TEEYER work at site in all year round. Nearly ten professional and qualified installation teams are perennially working for TEEYER. TEEYER has established a corporate standard for AAC equipment installation and acceptance, and in the declaration of project group standards as well. To provide effective supports for the high-precision installation, TEEYER purchased high-precision engineering surveying and mapping instruments above first class, such as level gauge and theodolite, etc.

- In order to provide professional production formula and production management services, TEEYER recruits several full-time experts with rich experiences, and also has long-term cooperation with some consulting companies, guaranteeing a full range consulting services to our customers.

- Full-time civil engineers are recruited by TEEYER to provide professional and instant technical guidance during civil construction.

- TEEYER maintains a cooperative relationship with many norms setting units related to architectural design and wall construction, like China AAC Association and National Wall Association, keeping abreast of policy trends and the latest construction requirements, so as to provide customers with policy consultation and construction technical guidance.

- TEEYER shares sourcing information with Komatsu, Hyundai and other certain Fortune 500 companies and holds first-level distribution qualifications from SEW, Siemens, Schneider, etc.

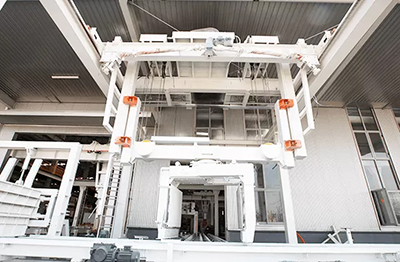

- TEEYER is armed with powerful manufacturing, mechanical processing, and post-painting capabilities for large-scale structural parts, equipped with several large-scale NC processing machinery, welding robots, three-coordinate high-precision measuring instruments and other advanced equipment. The processing capabilities and processing accuracy are far superior to others.

- TEEYER adopts the self-assembled hydraulic system which has the same configuration as KOMATSU, HYUNDAI and other high-end construction machinery. This system is able to work continuously and stably under high temperature.

- TEEYER electrical intelligent control system was applied in Europe imported AAC production line in China, and is widely used by high-end AAC producers such as Nanjing Xujian, Beijing Jinyu, and Fuyang Hangjia, etc. in China AAC industry.

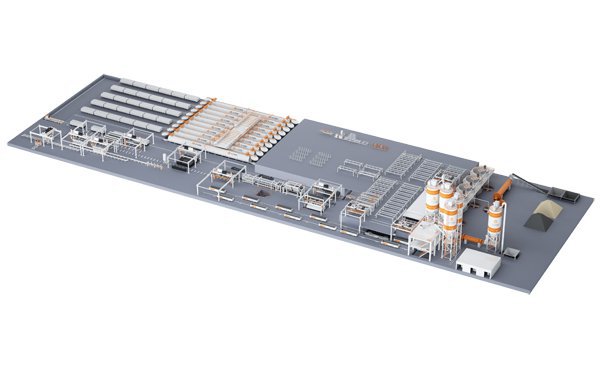

Main Products

-

- Raw Material Processing SectionAs the first part of the AAC block production line, the raw material preparation section includes several...

-

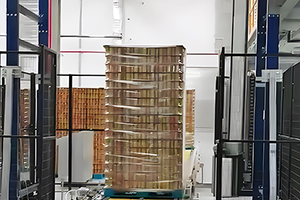

- Automatic Steel Mesh Fabricating and Circulating SectionThe straightened steel bars are welded into steel mesh automatically...

-

- Pouring & Pre-Curing SectionIn the batching and pouring section, you can find a range of related machines including...

-

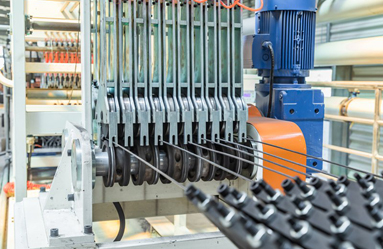

- Cutting SectionThe pre-cured concrete block in the mould will be cut into pieces as needed by the AAC cutting machine. ...

-

- Autoclaving SectionThe autoclaving section is a critical part of the entire AAC production line. It includes traction mechanism...

-

- Finished Products Packing SectionDCS automation control system is composed of Siemens PLC hardware, that is decentralized ...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی