Pouring & Pre-Curing Section

In the batching and pouring section, you can find a range of related machines including slurry scale, slurry storage container, aluminum powder mixer, ball mill, bucket elevator, and so on. The prepared materials will be mixed in a certain ratio, and then poured into the moulds. After years of optimization, the batching accuracy is quite desirable.

-

- Slurry and Powder Material Scale SystemSand slurry and waste slurry shall be measured by electronic scale, while cement and lime shall be measured by powder scale according to the proportion requirement.Read More

-

- Pouring MixerThe weighted slurry, waste slurry, water, cement, lime and aluminum paste will be added into mixer in sequence. The high speed mixing will make the slurry into...Read More

-

- Aluminum Powder Automatic Measuring And Mixing Systemaluminum powder is measured according to a set value and then put into the pouring mixer automatically. In our AAC production line...Read More

-

- Up-and-down Pouring DeviceThe up-and-down pouring device is a key unit of the AAC block pouring machine. It comprises pouring nozzle, lifting arm, and air compressor cylinder.Read More

-

- Pouring Ferry Push CarThe pouring ferry push car is at the batching and pouring section of AAC production line. It is composed of a working station...Read More

The slurry material in the mould is carried by the ferry cart to the pre-curing area. The pre-curing processing will take 2-3 hours, at this section, the material will turn to solid state from soft, to meet the required hardness.

-

- Mold and Side PlateThe mould is a recyclable part for AAC production line. Together with side plate, the AAC block mould or AAC panel mould is used for holding...Read More

-

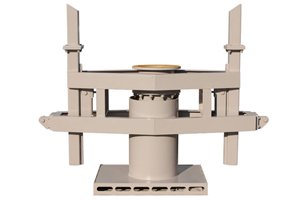

- Traction MechanismThe traction mechanism is a useful hauling device for the AAC production line, specifically in the pre-curing section. It can hook and push the mould...Read More

-

- Holding Pin Inserting and Drawing HoistThe holding pin inserting and drawing hoist is a critical machine for the AAC panel manufacturing. It is mounted below the traveling crane...Read More

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی