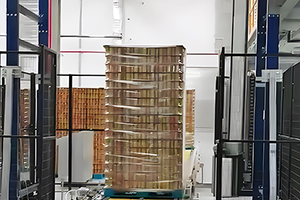

Pre-curing System

The slurry material in the mould is carried by the ferry cart to the pre-curing area. The pre-curing processing will take 2-3 hours, at this section, the material will turn to solid state from soft, to meet the required hardness.

Teeyer advantages: The pouring mixer equipped with 90kW high power motor, which can achieve high efficiency mixing within 3.5 minutes. Stirring blades adopt high alloy wear-resistant material. Single blade and double blade can achieve coaxial exchange.

-

- Mold and Side PlateThe mould is a recyclable part for AAC production line. Together with side plate, the AAC block mould or AAC panel mould is used for holding the slurry material from the pre-curing section to the cutting section. The needed type and quantity of the mould depend on the expected annual production capacity. Our mould consists of steel channel and steel plate, so it is strong and durable. Read More

-

- Traction MechanismThe traction mechanism is a useful hauling device for the AAC production line, specifically in the pre-curing section. It can hook and push the mould or hardening car. Usually this hauling device is used for transferring mould in the pre-curing section and hardening car before/after autoclave. The main components of our traction mechanism include motor, steel wire spooler, stretching device, hooking/pushing device, and steel rope.Read More

-

- Holding Pin Inserting and Drawing HoistThe holding pin inserting and drawing hoist is a critical machine for the AAC panel manufacturing. It is mounted below the traveling crane which can drive the hoist up and down. During the AAC panel production, the holding pin inserting and drawing hoist carries the coated reinforcement meshes or cages to an appointed place.Read More

The pre-curing section includes several important components like AAC block mould, side plate, traction mechanism, etc. These devices work perfectly with each other, transferring the slurry in the mould to the next section.

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی