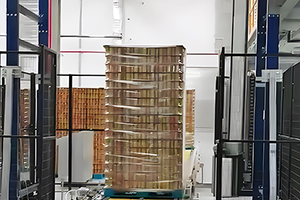

Slurry Storage Tank

After ball mill, the slurry will be pumped to the slurry storage tank, the agitator of tank will work constantly to avoid slurry sedimentation.

Using laser, ultrasonic, radar and other material level gauges to detect the tank slurry level.

As an important part of our autoclaved aerated concrete equipment, the slurry storage tank consists of silo, gear reducer, mixing spindle, movable frame, and central fulcrum. It is mainly used for storing the prepared fly ash slurry or sand slurry, while a mixing device is available for avoiding sedimentation.

The features of our slurry storage tank include easy maintenance, low energy consumption, and remarkably reduced installed capacity. Specifically, the energy consumption of our slurry tank could be reduced by at least 40%, and the fault could be decreased by around 5%. Besides, the material accumulated around the inner wall of traditional silo won't appear in ours. The effective volume of the container is above 100m2, while the planetary driving system is used for the mixing. The silo of our slurry storage tank are available with a wide range of capacity, from 8m3, 20m3, 50m3, 100m3, 150m3, up to 200m3.

Get In Touch

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of TEEYER is the whole line equipment for AAC block and panel production. TEEYER aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, TEEYER Company set up in the year of 1989, with 160.7 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

-

- Dowel-Inserting and Dowel-Drawing Out HoisterAssembled steel frames or steel cages are inserted in mould then pull out from mould...

-

- Mesh Assembly Frame Conveyor LineThis conveyor line consists mesh assembly frame rack, mesh assembly frame ferry cart...

-

- Anticorrosive Liquid Dipping and Drying SystemThe dipping hoister will carry assembled frames and cages to put them into anticorrosive...

-

- Slurry and Powder Material Scale SystemSand slurry and waste slurry shall be measured by electronic scale, while cement...

-

- Pouring MixerThe weighted slurry, waste slurry, water, cement, lime and aluminum paste will be added into mixer in sequence.

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی