Pouring Mixer

The weighted slurry, waste slurry, water, cement, lime and aluminum paste will be added into mixer in sequence. The high speed mixing will make the slurry into a uniform mixture with certain density, during this processing a heating device may be required.

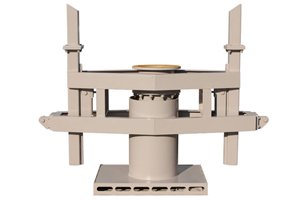

The pouring mixer is one of the core equipment for the AAC block machine. It is a combination of mixing equipment and pouring machine, and can mix all the materials needed in a very short time. For the production line, the main materials in the pouring mixing machine include fresh slurry, waste slurry, lime, cement, gypsum and aluminum powder. According to clients’ and process requirements, our pouring mixer is available in two types, regular speed mixer and high speed mixer.

After being blended in the pouring mixer, the tempered slurry will be poured into moulds. The pouring process is controlled by the pneumatic butterfly valve. Before the pouring process, the mixing device should get all the materials, including the aluminum powder, fully mixed in one minute, and the mixture will reach a certain temperature during the process. As the most critical equipment in the batching and pouring section, the pouring mixer has been well developed. It features high mixing speed, small installation area, easy operation, and adjustable pouring height.

Get In Touch

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of TEEYER is the whole line equipment for AAC block and panel production. TEEYER aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, TEEYER Company set up in the year of 1989, with 160.7 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

-

- Traction MechanismThe traction mechanism is a useful hauling device for the AAC production line, specifically in the pre-curing section.

-

- Holding Pin Inserting and Drawing HoistThe holding pin inserting and drawing hoist is a critical machine for the AAC panel manufacturing.

-

- Cross Cutting MachineFollowed by horizontal cutting, it is cross cutting area. The cake will be cut in vertical as required value.

-

- Vertical Cutting MachineAfter side cutting area, it is horizontal cutting. The horizontal cutting machine will cut the cake into several layers according to the set value.

-

- Cutting CarThe AAC cutting car system works around the cutting station. It consists of a cutting car, pinion and rack moving rail. In the cutting section...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی