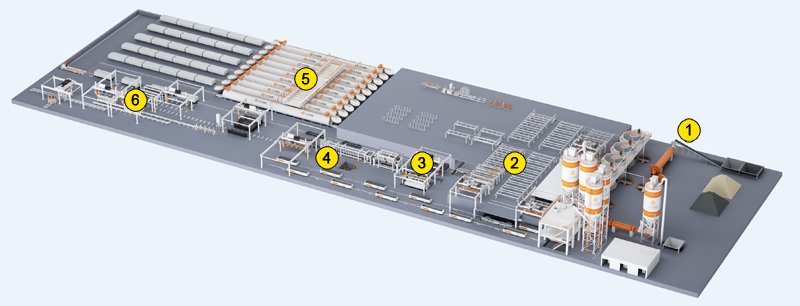

- Raw Material Processing Section

- Automatic Steel Mesh Fabricating and Circulating Section

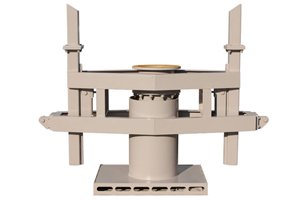

- Pouring & Pre-Curing Section

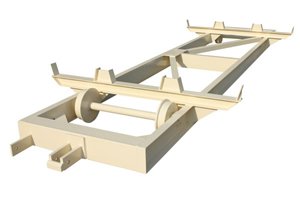

- Cutting Section

- Autoclaving Section

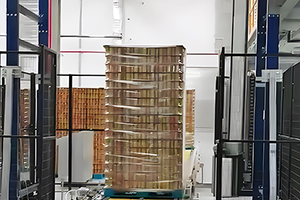

- Finished Products Packing Section

TEEYER has over 30 years of experience in the manufacturing of autoclaved aerated concrete production equipment. Our autoclaved aerated concrete block/panel production line comes with latest control algorithms for monitoring material batching, pre-curing, and controlling the later production processes. The whole production line could be divided into several sections including material preparing section, batching and pouring section, pre-curing section, cutting section, autoclaving section, and packaging section.

We have mastered a range of leading technologies in the AAC block making machine. Thus our concrete block/panel production line and each machine of it, and the service come with a lot of choices for you. With these choices, you can produce excellent autoclaved aerated concrete block and autoclaved aerated concrete panel attract more clients.

- The mold moves up and down together with the system completely synchronically.

- We have got patent for the driving mechanism which can drive the vibration grilling and the combination movements.

- The independent integrated hydraulic transmission unit comes with oil cooling system, heating device and rapid compensation mechanism.

- We purchase the key hydraulic component and electronic component from famous companies.

- A PLC device and a computer are available for the concrete block/panel production line. The operation interface is quite user-friendly, and the data input/output, and related diagrams are displayed on the screen. All the data related to production and operation could be also recorded.

As the first part of the AAC block production line, the raw material preparation section includes several machines like jaw crusher, ball mill, bucket elevator, etc. Each machine is perfectly integrated into the production line.

-

- Belt ScaleAdding a belt scale to the conveyor system is an excellent way to monitor the flow rate of material and ensure the accuracy of the totalized weight output. Read More

-

- Slurry AgitatorThere is a transition slurry pool next to the slurry storage tank, with two functions: one is to pump slurry to batching area, the other is to make connection with each single tank. Read More

-

- Slurry Storage TankAfter ball mill, the slurry will be pumped to the slurry storage tank, the agitator of tank will work constantly to avoid slurry sedimentation.Read More

-

- Mesh Welding MachineThe straightened steel bars are welded into steel mesh automatically, which is used for the preparation of AAC panel production..Read More

-

- Wax-dipping Lifting DeviceAssembled steel frames with steel pins together to be lifted by this device, dipping into wax, it will help to prevent...Read More

-

- Dowel-Inserting and Dowel-Drawing Out HoisterAssembled steel frames or steel cages are inserted in mould then pull out from mould by the hoister. The accuracy of the hoister...Read More

-

- Mesh Assembly Frame Conveyor LineThis conveyor line consists mesh assembly frame rack, mesh assembly frame ferry cart and other related devices. The line is a circulation conveying system. Read More

In the batching and pouring section, you can find a range of related machines including slurry scale, slurry storage container, aluminum powder mixer, ball mill, bucket elevator, and so on. The prepared materials will be mixed in a certain ratio, and then poured into the moulds. After years of optimization, the batching accuracy is quite desirable.

-

- Slurry and Powder Material Scale SystemSand slurry and waste slurry shall be measured by electronic scale, while cement and lime shall be measured by powder scale according to the proportion requirement.Read More

-

- Pouring MixerThe weighted slurry, waste slurry, water, cement, lime and aluminum paste will be added into mixer in sequence. The high speed mixing will make the slurry into...Read More

-

- Aluminum Powder Automatic Measuring And Mixing Systemaluminum powder is measured according to a set value and then put into the pouring mixer automatically. In our AAC production line...Read More

-

- Up-and-down Pouring DeviceThe up-and-down pouring device is a key unit of the AAC block pouring machine. It comprises pouring nozzle, lifting arm, and air compressor cylinder.Read More

The pre-cured concrete block in the mould will be cut into pieces as needed by the AAC cutting machine. The block appearance is largely affected by the performance of cutting machines. Due to the effective work by the subsequent machines like tongue and groove milling device, vacuum suction hood, and tilting table, each block will get 100% ready for autoclaving.

-

- Cross Cutting MachineFollowed by horizontal cutting, it is cross cutting area. The cake will be cut in vertical as required value. As the core equipment in an AAC production line...Read More

-

- Vertical Cutting MachineAfter side cutting area, it is horizontal cutting. The horizontal cutting machine will cut the cake into several layers according to the set value. Read More

-

- Cutting CarThe AAC cutting car system works around the cutting station. It consists of a cutting car, pinion and rack moving rail. In the cutting section...Read More

-

- Tongue and Groove Milling DeviceCutting cart carries side plate and cake to the tongue & groove area, to cutting the cake both two sides. Generally...Read More

The autoclaving section is a critical part of the entire AAC production line. It includes traction mechanism, ferry push car before/after autoclaving, AAC hardening car, and autoclave. Aerated concrete blocks will be autoclaved in the high temperature and high pressure environment provided by autoclave, a high pressure vessel.

-

- Traction MechanismThe traction mechanism is very important to the fluent operation of the AAC production line. It can push or haul the mold in the pre-curing section... Read More

-

- Ferry Push Car Before/After AutoclaveThe ferry push car before/after autoclave is located at the autoclaving section of AAC production line. It consists of working station...Read More

-

- Autoclave CartThe hardening car, located at the autoclaving section, is used for the material conveying in the AAC production line. It can endure the high temperature...Read More

As the last unit of our AAC block manufacturing line, the packaging section mainly comprise three machines, AAC block separator, finished product clamping hoist, and AAC block conveyor line, and so on. The highly automized process features high productivity and low labor intensity.

-

- Finished Product Clamping HoistFinished products will be lifted by clamping hoister, to leave side wall behind, and the side wall will be transferred... Read More

-

- Rotating HoisterFinished squeezed, blocks will be lifted by rotating hoister, on the length 1.2m direction, after 90 degree rotating, the blocks will be put in cross directions on the pallet. Read More

-

- Finished Product Conveyor LineThe finished product conveyor line is used for block conveying at the packaging section. As a chain conveyor...Read More

-

- Production Control SystemDCS automation control system is composed of Siemens PLC hardware, that is decentralized control and centralized management mode, low failure rate...Read More

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی