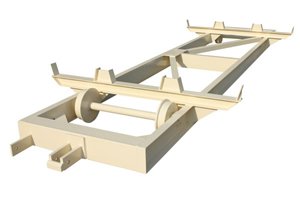

Ferry Push Car Before/After Autoclave

The driving part of ferry cart carries the autoclaved cake, to connect the autoclaving cart automatically, then pulling the cake out of autoclave. The first autoclaving cart will unhook connection with driving part, then transferred by ferry cart to return rail, the unloading area.

The auto-autoclaving system will adjust steam supply regularly by the set value, to avoid all unexpected issues, such as half steamed products or watermarked products. The waste heat recovery system will help to achieve a fast, energy saving and environmental protection production.

The ferry push car before/after autoclave is located at the autoclaving section of AAC production line. It consists of working station, friction wheel/hooking and pushing mechanism, walking wheel, and positioning device. The ferry push car can stop, position, and get aligned to the rails accurately after rapid transverse movement. When being loaded, the ferry push car can convert the frequency and run slowly. However, the empty car can run quickly also by converting the frequency when it is returning.

Get In Touch

Jiangsu Teeyer Intelligent Equipment Co., Ltd. is a high-tech enterprise specialized in building materials equipment designing, R&D, manufacturing, project management and integration of operation & maintenance. The main product of TEEYER is the whole line equipment for AAC block and panel production. TEEYER aims to provide customers with satisfactory overall solution for wall material products.

Located in High-tech Zone, Changzhou City, TEEYER Company set up in the year of 1989, with 160.7 million yuan registered capital, 143,000 square meters covering area, and over 400 employees, among them more than 80 administrative staff and senior R&D technicians.

-

- Finished Product Clamping HoistFinished products will be lifted by clamping hoister, to leave side wall behind, and the side wall will be transferred...

-

- Rotating HoisterFinished squeezed, blocks will be lifted by rotating hoister, on the length 1.2m direction, after 90 degree rotating, the blocks will be put in cross directions on the pallet.

-

- Finished Product Conveyor LineThe finished product conveyor line is used for block conveying at the packaging section. As a chain conveyor...

-

- Packaging MachinePackaging machine will strap goods in horizontal direction or vertical direction automatically, ready for storage or shipment.

-

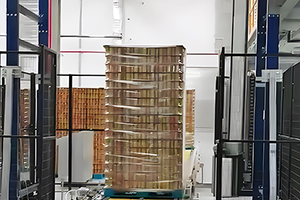

- Stretch Film MachineUsing stretch film to cover packages outside, to protect goods from water or dust.To realize separation on 5cm...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی