Teeyer Intelligent has once again collaborated with its long-term partner of 20 years, Lingxin Wall Material, to build an AAC block production line with an annual capacity of 1,000,000 cubic meters. The project, funded by Lingxin Wall Material, has officially commenced production.

The successful completion of this project marks a significant step forward for Lingxin Wall Material, further increasing its production capacity and strengthening its competitiveness in the domestic autoclaved aerated concrete (AAC) product industry.

Huzhou Linghu Lingxin Wall Material Co., Ltd., a renowned enterprise in the autoclaved aerated concrete (AAC) industry, stands as one of the earliest manufacturers in the Jiangsu-Zhejiang region to produce AAC products. With a robust dealer network and an excellent reputation, it has become a key supplier in Jiangsu-Zhejiang and neighboring regions.

The partnership between Lingxin Wall Material and Teeyer Intelligent began 20 years ago. From the installation of the first AAC production line with an annual capacity of 120,000 cubic meters in 2004, to the adoption of Teeyer’s standard 6*1.2m model and a 1-million-cubic-meter production line, this collaboration has mirrored the growth of China’s AAC industry, technological progress, and the booming Chinese AAC market.

Teeyer Intelligent’s unwavering commitment to product quality, service excellence, and technological innovation has cemented its position as an industry leader. Lingxin Wall Material’s decision to partner with Teeyer Intelligent once again reaffirms the company’s reputation as the only publicly listed enterprise in the AAC whole-line equipment sector.

A key feature of this project is the high-capacity AAC block production line, achieving an annual single-line production capacity of 1 million cubic meters with a mould production cycle of less than 100 seconds. Teeyer Intelligent emphasizes research and development, continuously overcoming technological challenges with its patented technologies and experienced R&D team. This project integrates several innovative designs and upgrades:

- Pouring Mixer

As the core equipment of the autoclaved aerated concrete production line, the Pouring Mixer was customized by Teeyer to meet the client’s requirements for ultra-high capacity and fast production. It features a double-layer paddle design, driven by a high-power motor for high-speed mixing. Combined with high-temperature pouring technology, this ensures efficient and stable operation of the 1-million-cubic-meter production line. - Cake-Waste-Removing Station

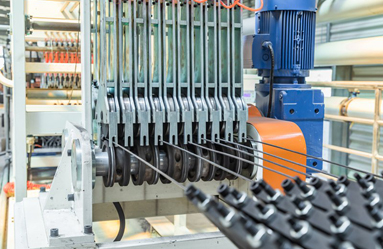

The Cake-Waste-Removing Station is equipped with a new overhead rotation crane integrated with grouping functionality. The crane rotates and removes bottom-layer waste during transportation, significantly improving production efficiency. - Cutting Machine Automation

A servo control system was implemented for the cutting machine, enabling precise control of cutting depth through servo-drive side cutting. This system ensures smoother and more uniform cutting surfaces, accurate adjustment of each steel wire’s cutting position, and compensation for material loss. Additional features include wire breakage alarms and automatic wire cleaning, enhancing dimensional accuracy and reducing manual errors. - Intelligent Hydraulic Tensioning System

To maintain high product quality in a competitive market, Teeyer’s R&D team developed a new servo replacement and intelligent hydraulic tensioning system. The flexible control system for the cutting machine supports a fast production cycle while ensuring consistent product quality, achieving a high pass rate for finished products.

These advancements reflect Teeyer Intelligent's commitment to technological innovation, helping clients like Lingxin Wall Material stay competitive in the AAC product industry.

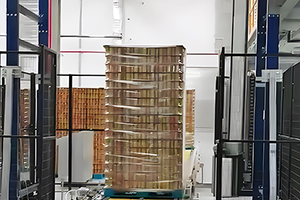

Lingxin Wall Material’s plant is strategically located near water ports, power plants, and cement factories, providing natural advantages in transportation and raw material costs. However, the limited land area posed a challenge for installing a large-scale, high-capacity production line. Teeyer’s R&D team customized the plant design to maximize land use, optimize investment costs, and enhance customer benefits.

- Optimized Pre-Curing Section

The pre-curing section uses double-mould synchronous ferry carts and multi-mould positions with friction wheel drives, minimizing the space needed for the pre-curing room. This design extends the green cake foaming time, ensuring product quality while significantly reducing binding material usage, thereby lowering production costs. - Short-Distance Autoclave Grouping Layout

An innovative layout featuring three cart positions in front of the autoclave and one behind integrates friction wheel and traction mechanism drives. This setup facilitates the fast movement of cakes in and out of autoclaves, supporting high-capacity and high-quality production while minimizing space requirements and investment costs. - Servo-Driven Green Cake Transport System

The production line employs a servo-driven system for green cake transport, offering improved positioning accuracy and speed control. This system quickly responds to input signals, ensuring efficient equipment operation and reducing energy consumption. - Hydraulic Servo System

The hydraulic servo system responds to system flow within milliseconds, enabling precise and efficient operation. This system reduces waste, saves energy, and enhances oil temperature control, seal life, hydraulic accuracy, and noise reduction, further improving environmental sustainability. - Efficient Project Execution

Despite a tight construction schedule, the production line was fully operational within six months of signing the contract. Equipment shipment, installation, commissioning, and official production were completed in just three months, saving significant time for the client. This demonstrates Teeyer Intelligent’s strong project execution capabilities and earned high praise from the client.

Founded in 1989, Teeyer Intelligent adheres to a pragmatic, professional, innovative, and win-win business philosophy. To date, the company has built over 1,200 autoclaved aerated concrete (AAC) panel and block production lines, exporting to more than 20 countries and regions worldwide.

On October 23, 2023, Teeyer Intelligent was successfully listed on the Shanghai Stock Exchange Main Board. Looking ahead, the company remains committed to pursuing excellence, staying true to its founding mission, and advancing with a global vision to establish “Teeyer Intelligent” as an exceptional global brand.

-

- Raw Material Processing SectionAs the first part of the AAC block production line, the raw material preparation section includes several...

-

- Automatic Steel Mesh Fabricating and Circulating SectionThe straightened steel bars are welded into steel mesh automatically...

-

- Pouring & Pre-Curing SectionIn the batching and pouring section, you can find a range of related machines including...

-

- Cutting SectionThe pre-cured concrete block in the mould will be cut into pieces as needed by the AAC cutting machine. ...

-

- Autoclaving SectionThe autoclaving section is a critical part of the entire AAC production line. It includes traction mechanism...

-

- Finished Products Packing SectionDCS automation control system is composed of Siemens PLC hardware, that is decentralized ...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی