Xinfa Group is Teeyer Intelligent’s most significant partner in terms of both project scale and quantity. Since 2018, the two companies have jointly established 16 autoclaved aerated concrete (AAC) production lines across four major bases located in Chiping (Shandong), Yulin (Shaanxi), and Changji (Xinjiang). Recently, Teeyer Intelligent supported Xinfa in a full-scale intelligent upgrade of its AAC facilities, enhancing production efficiency and boosting market competitiveness.

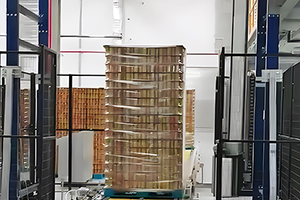

During this upgrade, Teeyer introduced a pioneering combination of rotary and extraction clamps, enabling automated block removal and palletizing. Packing height can now be flexibly adjusted to meet customer specifications.

The upgraded system achieved a record-breaking 55-second packing cycle for single pallets—a landmark achievement in China’s AAC industry. Coupled with automated loading systems, this dramatically improved the ACC line’s efficiency, reduced pallet-related costs (procurement, maintenance, storage), increased truck loading capacity, and ultimately cut logistics expenses—yielding significant economic benefits.

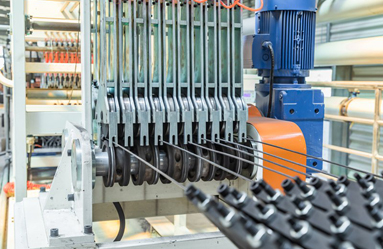

At Xinfa’s Chiping production base in Shandong, Teeyer further upgraded the pre-curing chambers and cutting sections. Key improvements included expanding mold stations, speeding up demolding and cutting, and implementing a fully automated mesh reinforcement system for tasks such as fiber cleaning, steel frame positioning, mesh circulation, and assembly. Following these upgrades, the daily output at the Xinyuan and Haoji plants surpassed 20,000 cubic meters, increasing overall efficiency by nearly 30%. This achievement not only set a provincial benchmark but also established Xinfa among the national leaders in AAC block production. The enhancements further bolstered Xinfa’s production strengths and its ability to meet regional demand.

In response to market needs, Xinfa developed three innovative product systems: fly ash panels, insulated sandwich blocks, and composite insulation boards. These advances overcame key technical barriers to large-scale production and enabled the recycling of industrial solid waste. The new product lines support the development of green construction while reinforcing Xinfa’s position as a technological leader in the industry.

Xinfa Group has deeply integrated smart technologies, automation, and lean manufacturing to build an advanced modern production system. As one of China’s Top 500 private enterprises, Xinfa pioneered a comprehensive production model combining:

- Dark Factories: Fully automated, 24/7 operations without manual intervention.

- Dust-Free Workshops: Precision control of temperature and air purity ensures product quality.

- Green Workshops: Waste heat recovery and renewable energy generation complete a sustainable, closed-loop production process.

Through lean management, Xinfa optimized its entire production workflow—achieving industry-leading standards in efficiency, stability, and sustainability. This “Intelligence + Automation + Lean” model now serves as a benchmark for the AAC sector.

Xinfa’s leadership is built on a fully integrated, closed-loop industrial ecosystem. By leveraging its resource coordination capabilities, Xinfa has established multiple AAC block production bases that utilize recycled industrial waste while also manufacturing core raw materials (lime, cement, aluminum powder) and auxiliary materials (packing straps, mould-release oil) in-house. This vertically integrated supply chain significantly reduces costs and ensures Xinfa's continued leadership in product quality, reputation, and capacity—even during industry slowdowns.

Looking ahead, Teeyer Intelligent will take the Shandong Xinfa model as a blueprint to further enhance end-to-end industry integration. Driven by continuous technological innovation, Teeyer aims to lead the AAC industry toward higher efficiency, lower carbon emissions, and intelligent production—delivering greater value for global clients.

-

- Raw Material Processing SectionAs the first part of the AAC block production line, the raw material preparation section includes several...

-

- Automatic Steel Mesh Fabricating and Circulating SectionThe straightened steel bars are welded into steel mesh automatically...

-

- Pouring & Pre-Curing SectionIn the batching and pouring section, you can find a range of related machines including...

-

- Cutting SectionThe pre-cured concrete block in the mould will be cut into pieces as needed by the AAC cutting machine. ...

-

- Autoclaving SectionThe autoclaving section is a critical part of the entire AAC production line. It includes traction mechanism...

-

- Finished Products Packing SectionDCS automation control system is composed of Siemens PLC hardware, that is decentralized ...

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی