Batching and Pouring Section

In the batching and pouring section, you can find a range of related machines including slurry scale, slurry storage container, aluminum powder mixer, ball mill, bucket elevator, and so on. The prepared materials will be mixed in a certain ratio, and then poured into the moulds. After years of optimization, the batching accuracy is quite desirable.

-

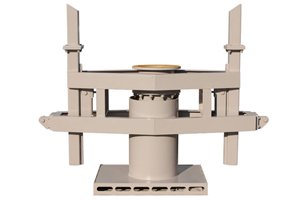

- Slurry and Powder Material Scale SystemSand slurry and waste slurry shall be measured by electronic scale, while cement and lime shall be measured by powder scale according to the proportion requirement.

The slurry/powder scale is important instrument for the weight batching system of the autoclaved aerated concrete line. It can serve as both a slurry weight scale and a powder weight scale. Its main components include hopper, supporting ring, weight sensor and pneumatic butterfly valve.Read More

-

- Pouring MixerThe weighted slurry, waste slurry, water, cement, lime and aluminum paste will be added into mixer in sequence. The high speed mixing will make the slurry into a uniform mixture with certain density, during this processing a heating device may be required. The pouring mixer is one of the core equipment for the AAC block machine. It is a combination of mixing equipment and pouring machine, and can mix all the materials needed in a very short time. Read More

-

- Aluminum Powder Automatic Measuring And Mixing SystemAluminum powder is measured according to a set value and then put into the pouring mixer automatically.In our AAC production line, the aluminum powder mixer is used as a blending machine to mix the aluminum powder with the slurry. Teeyer supplies two types of aluminum powder mixer. The simple type is based on manually weighing and feeding which comprises mixing propeller, mixing shaft, motor, and a 0.052m³ tank.Read More

-

- Up-and-down Pouring DeviceThe up-and-down pouring device is a key unit of the AAC block pouring machine. It comprises pouring nozzle, lifting arm, and air compressor cylinder. It is mounted below the pouring mixer and is connected with the PLC control system. After mixing, the obtained slurry will be poured into the empty moulds. The number of big air bubbles in the mould is reduced and the AAC pouring area could be kept clean.Read More

-

- Pouring Ferry Push CarThe pouring ferry push car is at the batching and pouring section of AAC production line. It is composed of a working station, friction wheel or hooking and pushing mechanism, walking wheel, and positioning device. The ferry push car can stop, position, and get aligned to the rails accurately after rapid transverse movement. Read More

English

English English

English English

English Русский

Русский Español

Español العربية

العربية العربية

العربية Indonesia

Indonesia فارسی

فارسی